Willkommen beim Schneidemaschinen Portal – Schneidemaschinen für Papier & mehr

Außerdem findest du hier einige Fragen und Antworten für das Schneiden von Materialien.

Unsere beliebtesten Blogs:

Papierschneidemaschinen Blog

Du bist auf der Suche nach einer Papierschneidemaschine, die deinen Bedürfnissen entspricht? Dann bist du bei uns genau richtig!

Unsere Seite bietet dir hilfreiche Tipps, Vergleiche und Tests, damit du ganz bequem den perfekten Papierschneider finden kannst – egal ob für dein Büro oder dein Hobby.

Sechs beliebte Papierschneider Modelle im Vergleich

Du bist auf der Suche nach der perfekten Papierschneidemaschine, hast aber keine Zeit für eine ausführliche Recherche? Wir haben das Richtige für dich! Unsere Übersicht bietet einen kurzen Einblick in verschiedene Maschinentypen, während unsere Ratgeberseiten mehr Details bieten. Wenn du alle deine Optionen noch genauer unter die Lupe nehmen willst, schau dir unsere Vergleichsseite an – Modelle zu vergleichen war noch nie so einfach!

Auf unserer Testseite findest du die Ergebnisse und Videos für alle Maschinen. Mehr hilfreiche Informationen gibt es auf unserer Papierschneiderinfoseite.

Unsere Empfehlungen

Tests und Produktvorstellungen

Fellowes Fusion A4 Hebelschneidemaschine

★★★★ (3.6)

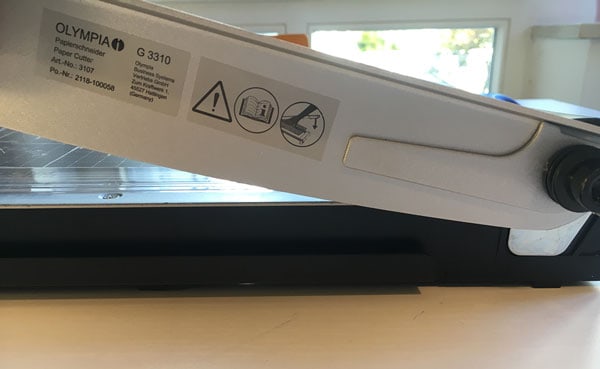

Im Test: Der Olympia G 3310 Hebelschneider

(Bewertung: 3.4)

Jielisi Papierschneidemaschine A4 12 Zoll

(Bewertung: 3.3)

Direkt zu Ihrem Thema!

- Welches ist das passende Papierschneidegerät und das ideale Zubehör für mich?

- Welche Papierschneidemaschinen eignen sich besonders gut zum Basteln?

- Welche Papierschneidemaschine für A3 gibt es?

- Welche Papierschneidemaschine für das Büro oder für Profis?

- Worauf sollte ich bei Angeboten achten?

- Sollte ich besser online oder beim Händler kaufen?

Was ist eine Papierschneidemaschine?

Papierschneidemaschinen machen das Schneiden zum Kinderspiel, denn sie bieten präzise und genaue Schnitte und nehmen dir die Zeit für die manuelle Arbeit ab. Egal, ob du einzelne Blätter oder Stapel zuschneiden willst, mit diesen Maschinen kannst du alles machen – von geraden Linien bis hin zu komplexen Designs! Für gerade Schnitte eignen sich Rollenschneidemaschine – für beliebige Muster empfehlen wir Schneideplotter.

Eine Papierschneidemaschine ist normalerweise nicht nur für Papier geeignet. Fotos, Folien, Kartons, Leder und Laminiertes können je nach Modell ebenfalls geschnitten werden.

Für die verschiedenen Anwendungen gibt es verschiedenen Arten von Papierschneidemaschinen. Im Folgenden finden Sie detaillierte Informationen zu diesen.

Ein Überblick über die wichtigsten Arten von Papierschneidemaschinen

Papierschneidemaschinen unterscheiden sich hinsichtlich der Technik und des Anwendungsbereichs. Deswegen stellen wir Ihnen kurz die verschiedenen Arten von Papierschneidemaschinen vor.

Die Rollenschneidemaschine

Rollenschneider schneiden das Papier, indem ein Rundmesser über das Papier gerollt wird. Mit Rollenschneidemaschinen lassen sich einzelne Blätter oder Fotos optimal zuschneiden. Außerdem besitzen viele Rollenschneider Wechselklingen, mit welchen sich Muster (z. B. Zickzack oder Büttenschnitt) schneiden lassen.

Deswegen werden Rollenschneider zum Basteln und Bearbeiten von Fotos verwendet.

Für wen?

Zum Basteln und Fotoarbeiten, also das Hobby, kleine Büro oder Grafikstudio.

Produkte & weitere hilfreiche Informationen zu Rollenschneidern!

Tipp: Unter dem Tag Hobby haben wir alle Papierschneidemaschinen und Themen für Heimarbeiten zusammengefasst.

Schnittschneidemaschine

Bei Schnittschneidern wird kein Rundmesser, sondern eine normale Klinge, auch Dorn genannt, über das Papier gezogen. Der Aufbau und der Anwendungsbereich sind ähnlich derer von Rollenschneidegeräten. Schnittschneidemaschinen sind oft günstiger als vergleichbare Rollenschneidemaschinen.

Der sogenannte Dorn muss jedoch tendenziell häufiger gewechselt und nachgekauft werden.

Produkte & weitere hilfreiche Informationen zu Schnittschneidern!

Für wen?

Zum Basteln und Fotoarbeiten, insbesondere für Heimanwender, aber auch gelegentlich im Büro.

Tipp: Unter dem Tag Hobby haben wir alle Papierschneidemaschinen und Themen für Heimarbeiten zusammengefasst

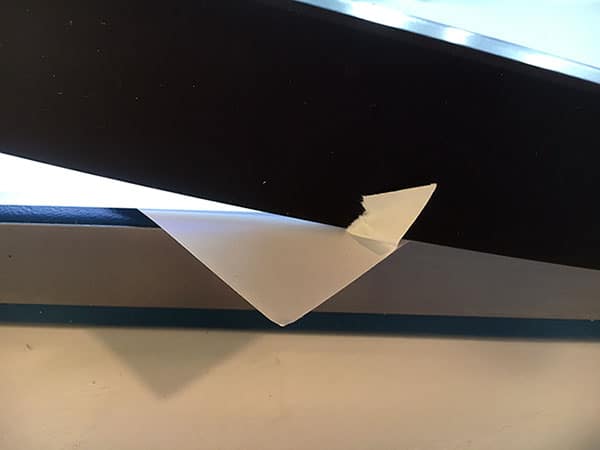

Die Hebelschneidemaschine

Eine Hebelschneidemaschine schneidet das Papier, indem eine lange Klinge durch das Papier gedrückt wird. Dies entspricht dem Prinzip einer Guillotine. Hebelschneidegeräte sind besonders gut geeignet, um lange, gerade Schnitte zu machen. Außerdem können dickere Materialien geschnitten werden. Hebelschneidemaschinen findet man häufig in Büros oder in Lehrerzimmern.

Produkte & weitere hilfreiche Informationen zu Hebelschneidern!

Für wen?

Im Büro, Lehrerzimmer und Zuhause ist der Hebelschneider gern gesehen.

Tipp: Unter den Tags Profi und Büro haben wir alle Papierschneider zu den Themen Büro und Profi zusammengefasst.

Der Rollschneider

Das Prinzip von Rollschneidern entspricht dem von Rollenschneidegeräten.

Rollenschneider werden jedoch nicht entlang einer Schiene über das Papier gezogen, sondern an einem Griff in der Hand gehalten und wie ein Tapeziermesser über das Papier gezogen. Ideal zum Basteln oder zum Zuschneiden von Stoff.

Produkte & weitere hilfreiche Informationen zu Rollschneidern!

Die Stapelschneidemaschine

Stapelschneidemaschinen sind dafür ausgelegt, dicke Stapel Papier zu schneiden. Dieser Papierschneider ist für den professionellen Bereich gedacht. Je nach Stapelschneider sind Stapel mit 400 Blättern kein Problem. Mit einem normalen Rollen- oder Hebelschneider können diese Stapel nicht zugeschnitten werden.

Produkte & weitere hilfreiche Informationen zu Stapelschneidern!

Die Atelierschneidemaschine

Atelierschneidemaschinen sind für den grafischen Bereich konzipiert.

Im Prinzip handelt es sich um einen Hebelschneider, der eine besonders lange Klinge besitzt. Mit einer Atelierschneidemaschine lassen sich sehr lange und große DIN-Formate zuschneiden. Ideal für sehr große Foto-Formate und Plakate.

Produkte & weitere hilfreiche Informationen zu Atelierschneidemaschinen!

Welches Schneidemaschinenmodell ist das beste? Worauf müssen Sie beim Kauf achten?

Es gibt viele verschiedene Papierschneidemaschinen, gute und weniger gute. Jedoch ist es schwierig zu sagen, welche „die Beste“ ist. Dies hängt ganz davon ab, was Sie mit der Papierschneidemaschine machen möchten. Zunächst sollten Sie sich überlegen, wofür Sie die Maschine benötigen. Die richtige Papierschneidemaschine sollte nicht nur eine angemessene Qualität besitzen, sondern auch für den Einsatzzweck geeignet sein.

Damit Sie wissen, auf was beim Kauf achten müssen, erklären wir Ihnen im Folgenden die wichtigsten Eigenschaften und Ausstattungsmerkmale von Schneidemaschinen für Papier.

Welche Papierschneidemaschine ist die richtige?

Je nach Art der Anwendung sollten Sie sich für einen Hebelschneider oder einen Rollenschneider entscheiden. Für welche Anwendung der jeweilige Schneider besser geeignet ist, das erfahren Sie hier!

Hebel- oder Rollenschneidemaschine? Welche Unterschiede gibt es?

Möchten Sie mit dem Papierschneider Basteln oder Fotos zuschneiden? Dann ist eine Rollenschneidemaschine wahrscheinlich die bessere Wahl. Möchten Sie lange gerade Schnitte durchführen und dabei ganze Papierstapel schneiden? Dann wiederum ist eine Hebelschneidemaschine die richtige für Sie.

Wir haben in einem detaillierten Beitrag die Vor- und Nachteile von Hebel- und Rollenschneidemaschinen zusammengefasst.

Rollen- und Hebelschneidemaschinen sind sich zwar ähnlich, der Aufbau ist doch recht unterschiedlich.

Rollenschneidemaschinen – Basteln, Fotozuschnitt und Muster

Rollenschneider besitzen ein Rundmesser, welches über das Papier gezogen wird. Hebelschneider besitzen ein langes Messer, mit dem das Papier ähnlich wie mit einem Beil geschnitten wird. Dieser Unterschied führt dazu, dass mit einer Rollenschneidemaschine einzelne Blätter oder Fotos sehr präzise zugeschnitten werden können.

Außerdem können auch verschiedenen Mustern zugeschnitten werden. Somit sind Rollenschneidemaschinen eher zum Basteln oder zum Zuschneiden von einzelnen Blättern tendenziell besser geeignet.

Mehr Informationen finden Sie auf unserer Infoseite zu Rollenschneidemaschinen.

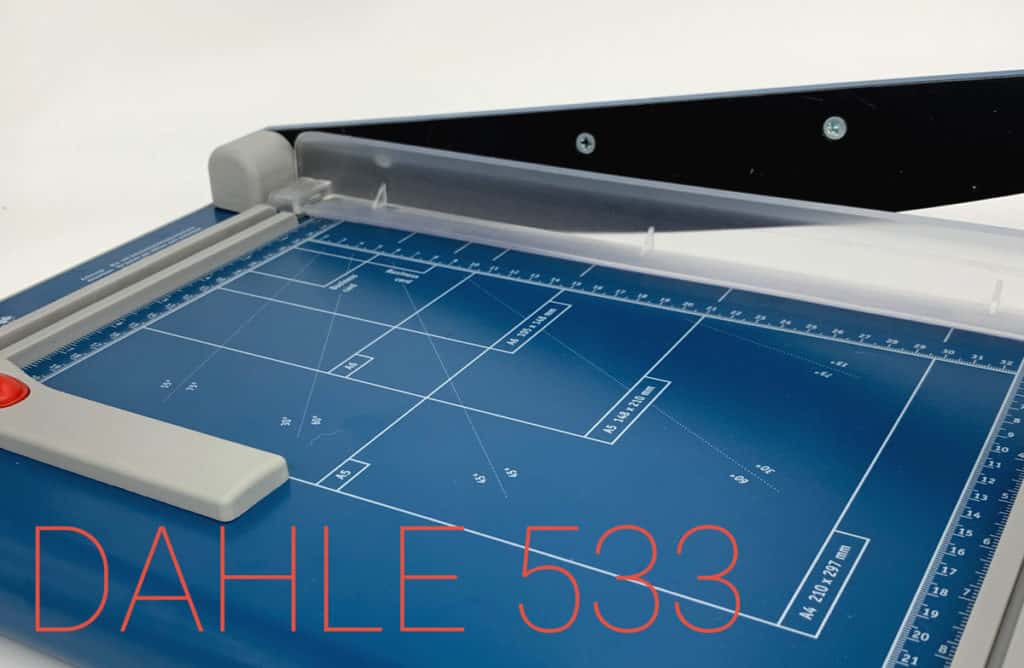

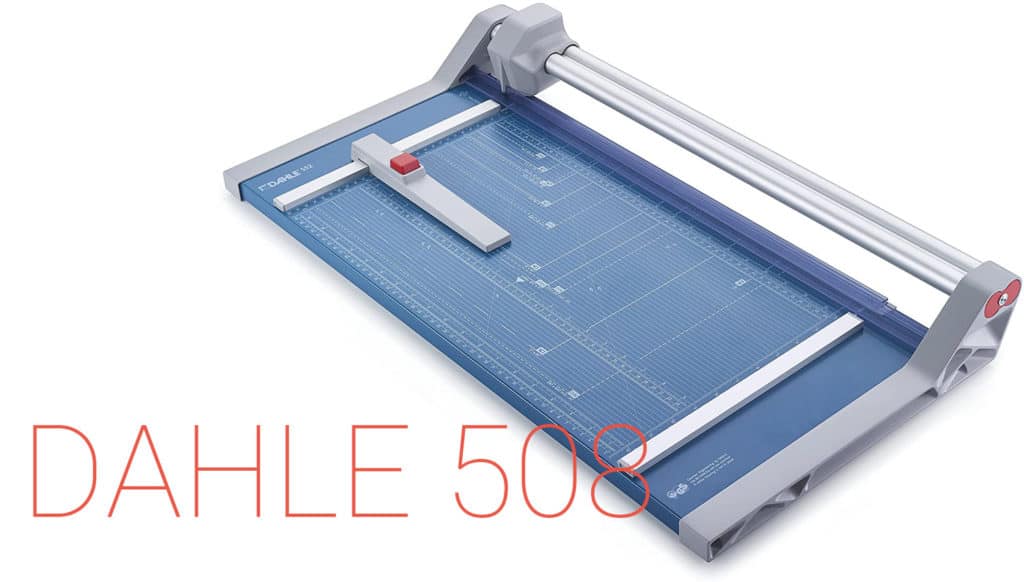

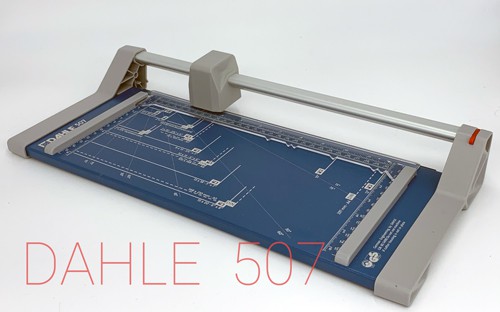

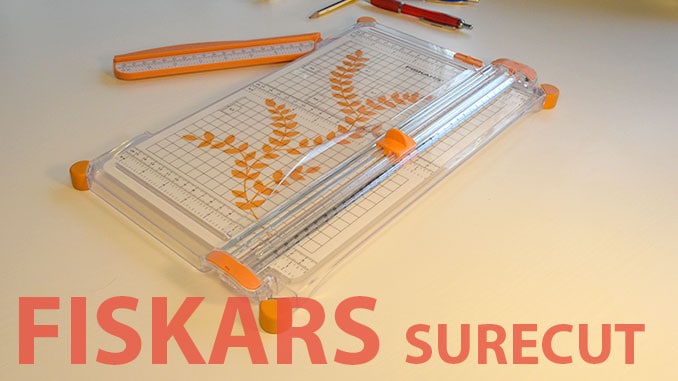

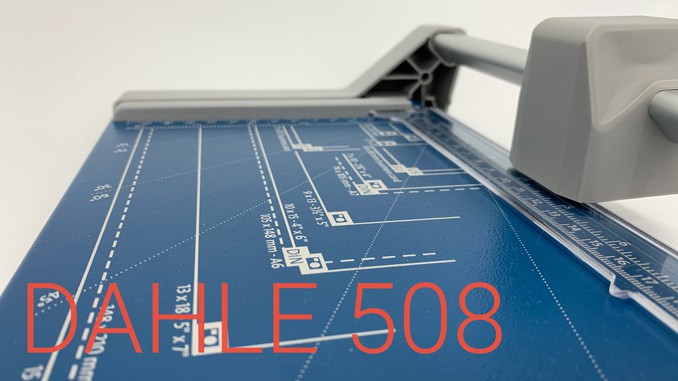

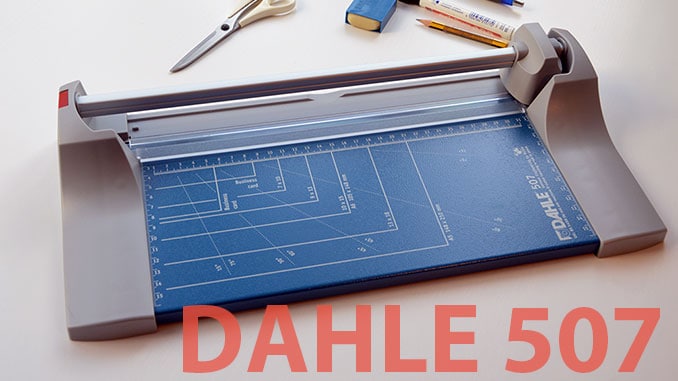

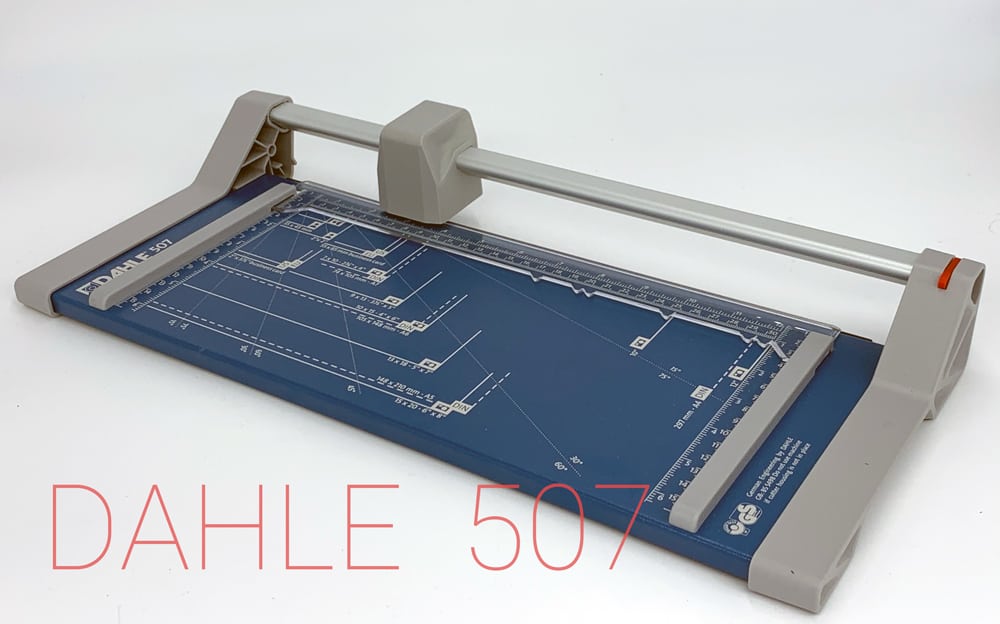

Beliebte Maschinen zum Basteln oder für den Fotozuschnitt im DIN-A4-Format sind die Dahle 507, die Zoomyo oder die Fiskars Surecut. Für Schnittlängen bis zu DIN A3 empfehlen wir die Dahle 508 und die Dahle 552.

Hebelschneidemaschinen – lange Schnitte, hohe Papierstapel

Im Gegensatz dazu sind Hebelschneidemaschinen ideal für lange und gerade Schnitte. Durch ihren Aufbau können auch dickere Stapel in nur einem Arbeitsgang geschnitten werden. Deswegen sind Hebelschneider eher für die geeignet, die Papierstapel auf ein bestimmtes Format zuschneiden möchten. Dekoschnitte sind mit Hebelschneidern nicht möglich.

Mehr Informationen finden Sie auf unserer Infoseite zu Hebelschneidemaschinen.

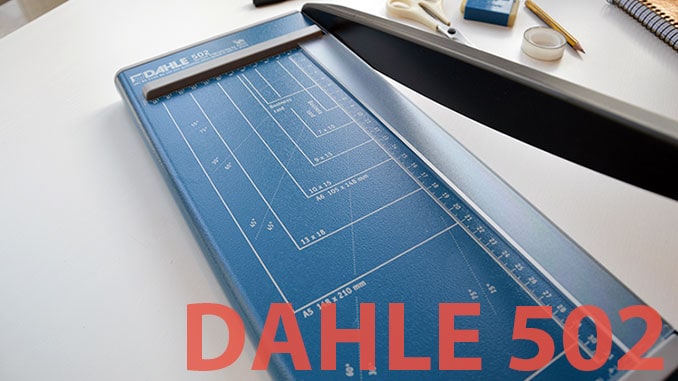

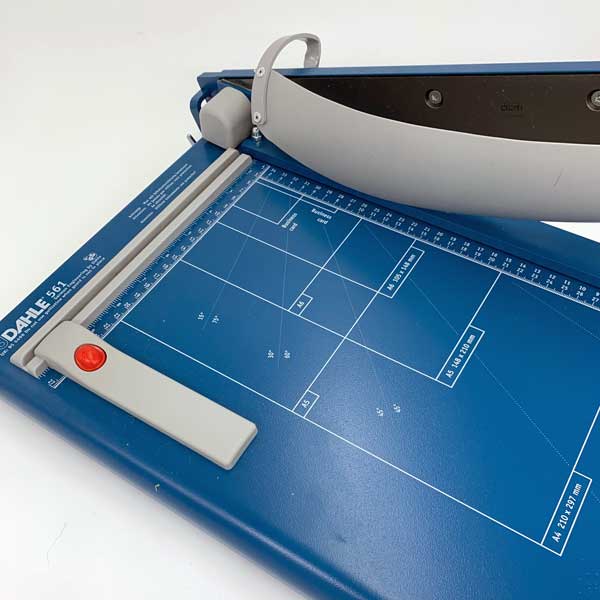

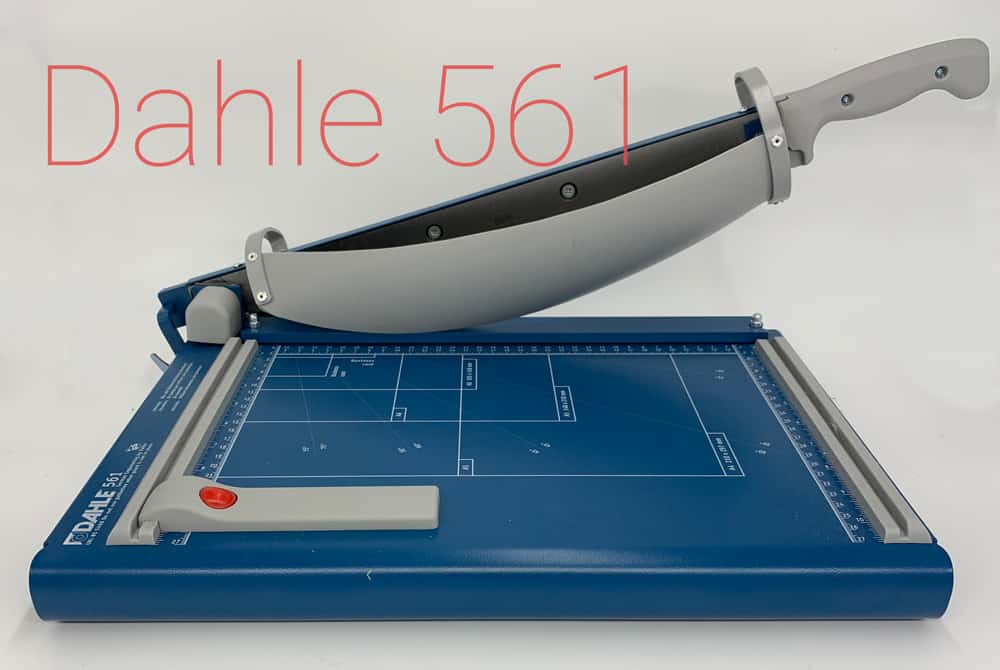

Beliebte günstige Hebelschneidemaschinen sind Dahle 502, Zoomyo und Genie GH40. Im mittleren Preissegment gehören zu unseren Bestsellern die Ideal 1133 und Dahle 533. Bei Profis ist die Dahle 561 sehr beliebt.

Welche weiteren Kriterien sind beim Kauf zu berücksichtigen?

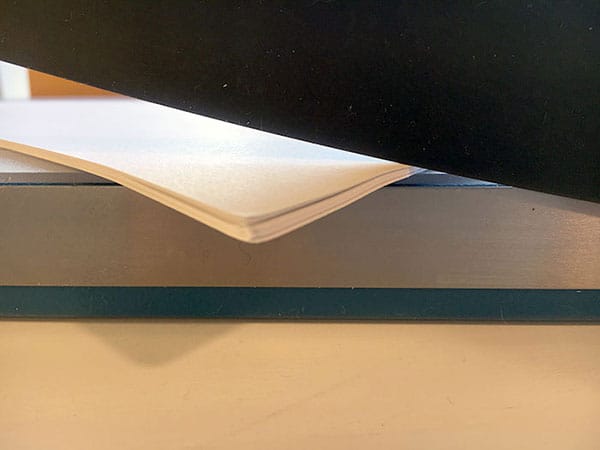

Die Schnitthöhe der Papierschneidemaschine

Die Schnitthöhe ist ein wichtiges Kriterium bei der Auswahl Ihrer Papierschneidemaschine. Mit dieser wird die maximale Höhe des Materials, das auf einmal geschnitten werden kann, bestimmt. Die maximale Schnitthöhe eines Papierschneiders kann sehr unterschiedlich ausfallen.

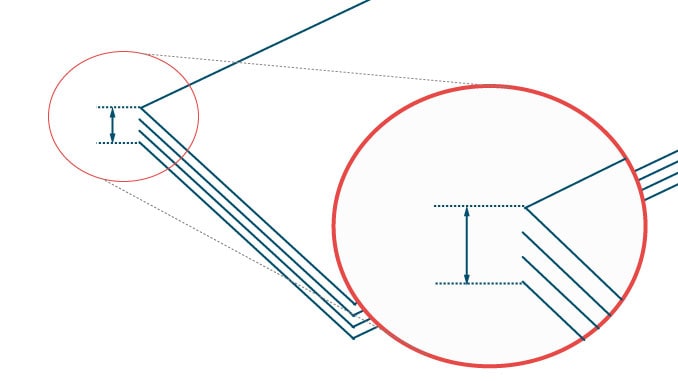

Die Schnitthöhenangabe

Hersteller geben die maximale Schnitthöhe auf zwei Arten an. Entweder wird die maximale Anzahl der Blätter oder die maximale Schnitthöhe in Millimetern genannt. Wenn die maximale Anzahl der Papierblätter angegeben wird, dann sollten Sie darauf achten, für welche Papierstärke diese Angabe erfolgt. In unseren Produktvergleichen haben wir 70 g/qm und 80 g/qm berücksichtigt. Außerdem haben wir untersucht, welchen Einfluss die Schnitthöhe auf den Kaufpreis hat.

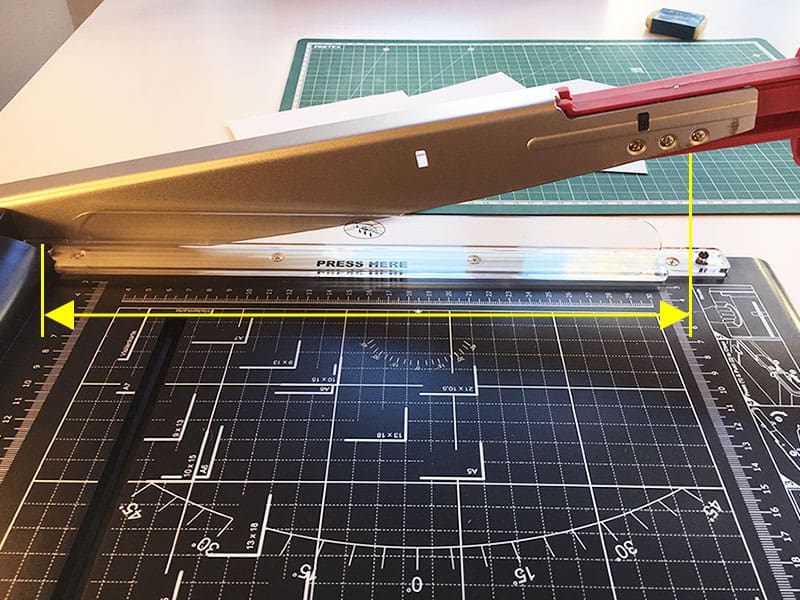

Die Schnittlänge – das maximale Format

Das maximale Format wird durch die Schnittlänge bestimmt. Eine Papierschneidemaschine A3 besitzt eine größere Schnittlänge als eine Papierschneidemaschine A4. Eine Papierschneidemaschine A0 ist wesentlich größer (und teurer) als kleinere Modelle.

Die Schnittlänge hängt bei einem Rollenschneider von der Länge der Schneideschiene ab. Bei einem Hebelschneider hingegen von der Länge der Klinge. Je länger diese sind, desto größer ist das maximal mögliche DIN-Format und die Schnittlänge der Papierschneidemaschine.

Eine scharfe und robuste Klinge

Egal, wie gut eine Schneidemaschine verarbeitet ist, eine scharfe und harte Klinge ist für die Qualität des Zuschnitts entscheidend. Egal, ob es das Rundmesser eines Rollenschneiders ist oder die Klinge eines Hebelschneiders, nur eine scharfe und gut verarbeitete Klinge sorgt für einen dauerhaft sauberen und präzisen Schnitt.

Achten Sie beim Kauf einer Papierschneidemaschine darauf, dass die Qualität des Messers gut ist. Wenn die Klinge stumpf ist, dann franst das Papier entweder aus oder es lässt sich überhaupt nicht mehr richtig schneiden. Mit dem Ergebnis eines solchen Schnitts werden Sie nicht zufrieden sein. Wichtig ist außerdem auch, wie stabil das Messer oder die Klinge verbaut ist. Schwache und unpräzise Halterungen sind schlecht für die Genauigkeit.

Doch, auch das beste Messer verschleißt mit der Zeit. Damit die Qualität des Zuschnitts weiterhin gut ist, kann das Messer bei vielen Modellen durch eine Ersatzklinge ausgetauscht oder nachgeschliffen werden. Bei einigen Rollenschneidern schärft sich das Rundmesser von selbst.

Weitere Informationen zu Rollen- und Hebelschneidemaschinen finden Sie in unserem Ratgeber.

Die Ausstattung

Sicherheit – Safety First

Jeder von uns weiß, dass man mit einer Schere aufpassen muss. Dies gilt auch für Papierschneidegeräte. Deswegen sollte ein ausreichender Schutz nicht vernachlässigt werden.

Rollenschneider sollten einen Schneidekopf besitzen, der das scharfe Rundmesser abkapselt. Die Klinge eines Hebelschneiders hingegen ist nicht scharf. Die Klinge ist robust und hart. Es besteht eher die Gefahr einer Quetschung. Deswegen sind gut ausgestattete Geräte mit Vorrichtungen ausgestattet, die verhindern, dass Finger nicht aus Versehen unter die Klinge gelangen.

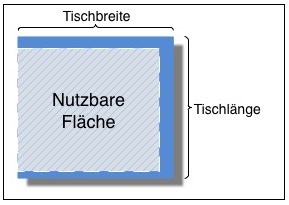

Die Tischgröße

Die Größe des Schneidetisches ist bei der Auswahl einer Papierschneidemaschine ein wichtiges Kriterium. Je größer der Tisch, desto größer das Format des Schnittguts (Fotos, Karton, Papier oder auch Folien). In der Regel können mit größeren Schneidemaschinen auch härtere und dickere Materialien geschnitten werden.

Je größer der Tisch ist, umso größer ist die Arbeitsfläche und somit das Papierformat. Normalerweise wird die Größe des Tisches des Papierschneidegeräts in den Produktbeschreibungen mithilfe der Tischlänge und Tischbreite angegeben. Die tatsächlich nutzbare Fläche ist normalerweise etwas kleiner. Winkelanlagen und die Befestigung der Klinge nehmen ebenfalls etwas Platz ein und verringern dadurch die Arbeitsfläche.

Deswegen ist der Platz zum Arbeiten oft kleiner als die Angabe der Tischgröße. Achten Sie deswegen immer auch auf die Formatangaben des Herstellers. Nur so können Sie Ihr gewünschtes Papierformat problemlos schneiden.

8 Bestseller & Angebote Papierschneidemaschinen

| | JIELISI Papierschneider (Bis 80g A4, 12 Blatt Schneidleistung) Manuell Schneidemaschine,...* * | 62 Bewertungen* | 29,99 EUR |

| | Papierschneider, A4 Papierschneider, Schneidemaschine mit Automatischer Sicherheits Sicherung,...* * | 12,99 EUR 9,99 EUR (−23%) | |

| | Meafeng Papierschneider 12 Zoll A4 Papier Schneidemaschine Schneidegerät Papier Cutter mit 2...* * | 18,99 EUR 13,99 EUR (−26%) | |

| | Dahle 502 Hebel-Papierschneider (bis DIN A4, Schnittlänge 320 mm, 8 Blatt Schneidleistung) Blau* * | 66,28 EUR 40,99 EUR (−38%) | |

| | Dahle 507 Papierschneider (8 Blatt Schneidleistung, bis DIN A4) blau* * | 43,88 EUR 34,74 EUR (−21%) | |

| | Hebelschneider A4 kompakt, Papierschneider aus Metall, Schneidemaschine Papier, Foto - Pappe bis...* * | 26,95 EUR | |

| | Dahle 533 Schneidemaschine (Bis DIN A4, 15 Blatt Schneidleistung) blau* * | 86,69 EUR | |

| | Leitz Precision Home Papierschneider A4, schneidet bis zu 8 Blatt, Schneidemaschine mit 305 mm...* * | 23,59 EUR 19,48 EUR (−17%) |

Tipp: Das maximale Format (DIN A4, A3, A2 …) wird normalerweise für die Längsseite des Papiers angegeben. Wenn die schmalere Seite geschnitten werden soll, dann ist dies auch für das nächstgrößere Format möglich. Wir versuchen, dies in unseren Produktvergleichen zu berücksichtigen.

Ausreichende Tischgröße

Wenn Sie nicht nur rechte Winkel zuschneiden möchten, dann sollten Sie darauf achten, dass der Tisch groß genug ist, um die Blätter entsprechend zu drehen.

Winkelanlagen

Winkelanlagen erleichtern das Arbeiten mit der Papierschneidemaschine. Diese grenzen die Tischfläche jeweils oben und unten ab.

Bei guten Schneidemaschinen sind diese Winkelanlagen natürlich so gewählt, dass sie mit der Schnittlänge optimal zusammenpassen. Außerdem lassen sich mithilfe dieser Winkelanlagen rechte Winkel präzise schneiden.

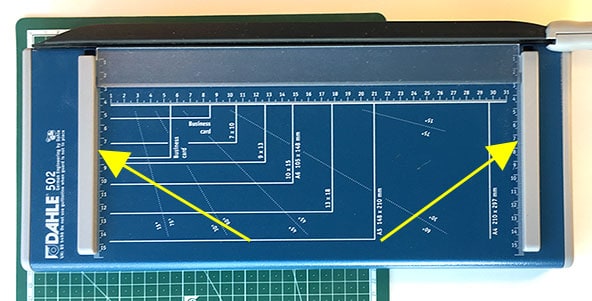

Längen- und Formatangaben

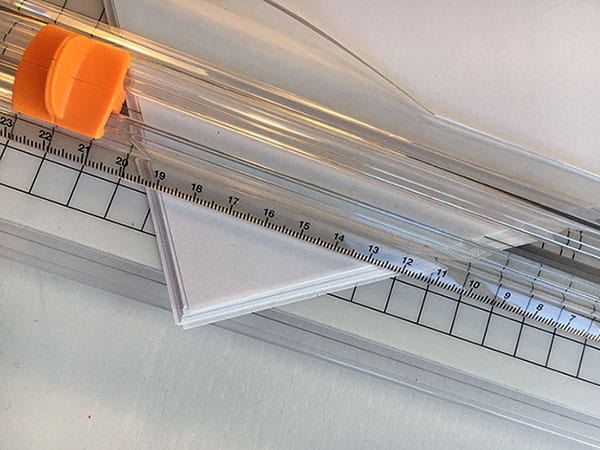

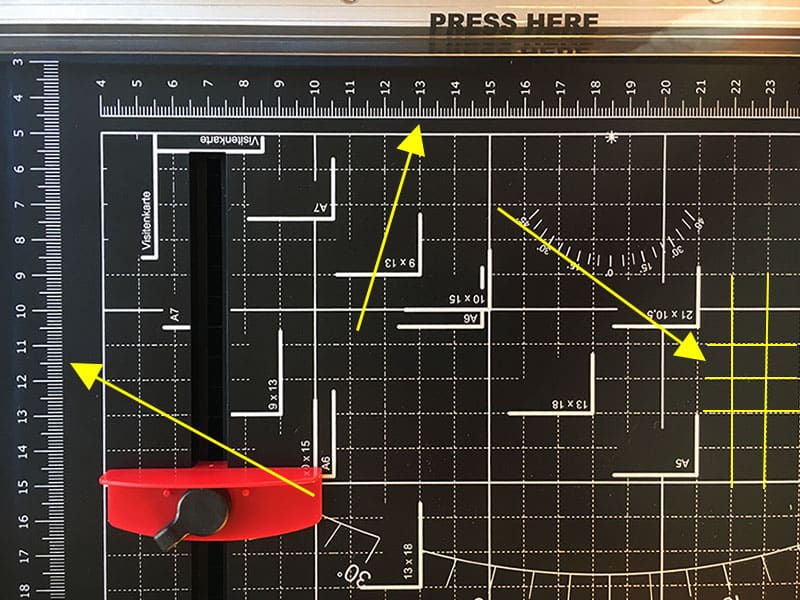

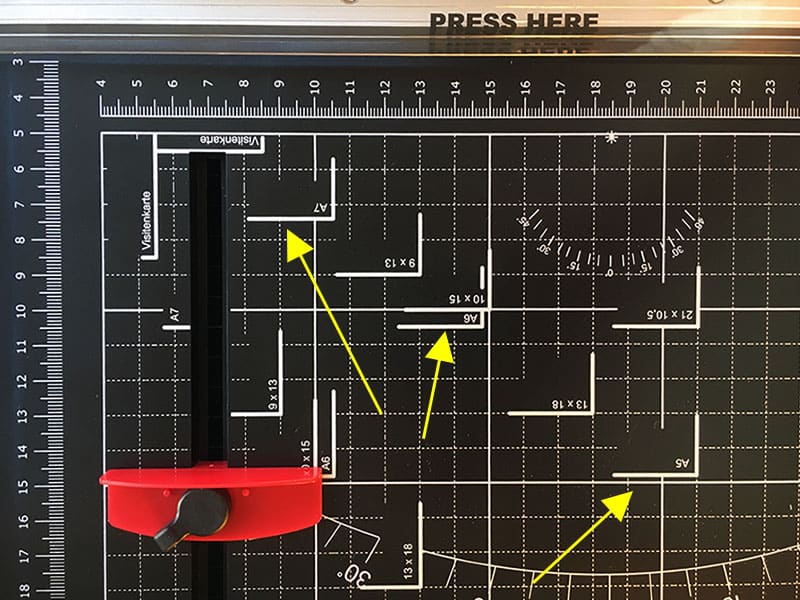

Lineale und Skalen

Eine scharfe Klinge reicht nicht aus, damit ein Schnitt gelingt. Der Schnitt muss ebenfalls an der richtigen Stelle erfolgen. Deswegen bieten Papierschneidegeräte unterschiedliche Hilfsmittel an, um ein präzises Arbeiten zu erleichtern.

Die Auswahl an Längenangaben ist umso umfangreicher, je professioneller eine Papierschneidemaschine ist. Folglich ist der Preis von professionellen Geräten oft höher als der von einfachen Einstiegsmodellen.

Ein Lineal oder eine Messskala kann an jeder Seite des Tisches der Papierschneidemaschine positioniert sein. In Deutschland werden normalerweise Zentimeter und Millimeter angegeben. Manchmal besitzen Papierschneider auch Zoll- oder Inch-Angaben. Praktisch sind die Längenangaben, um ohne großen Aufwand die entsprechenden Längen und DIN-Größen zuzuschneiden.

Hilfsraster

Neben Längenangaben sind auch Hilfsraster sehr hilfreich. Wenn kleinere Formate zugeschnitten werden sollen, dann sind diese besonders hilfreich. Die Abstände der Linien bei Papierschneidegeräten mit einem Hilfsraster beträgt normalerweise einen Zentimeter.

DIN Formatangaben

Neben Hilfsrastern sind DIN Formatangaben, wie DIN A4, DIN A3 oder DIN A2, äußerst nützlich. Wenn ein entsprechendes Format zugeschnitten werden soll, dann helfen diese Formatangaben dabei, dass dies einfach und schnell von der Hand geht.

Die wichtigsten DIN Papierformate und ihre zugehörigen Längen und Breiten in Millimeter.

| DIN | Seitenlänge | Seitenbreite |

| A0 | 841 mm | 1189 mm |

| A1 | 594 mm | 841 mm |

| A2 | 420 mm | 594 mm |

| A3 | 297 mm | 420 mm |

| A4 | 210 mm | 297 mm |

| A5 | 148 mm | 210 mm |

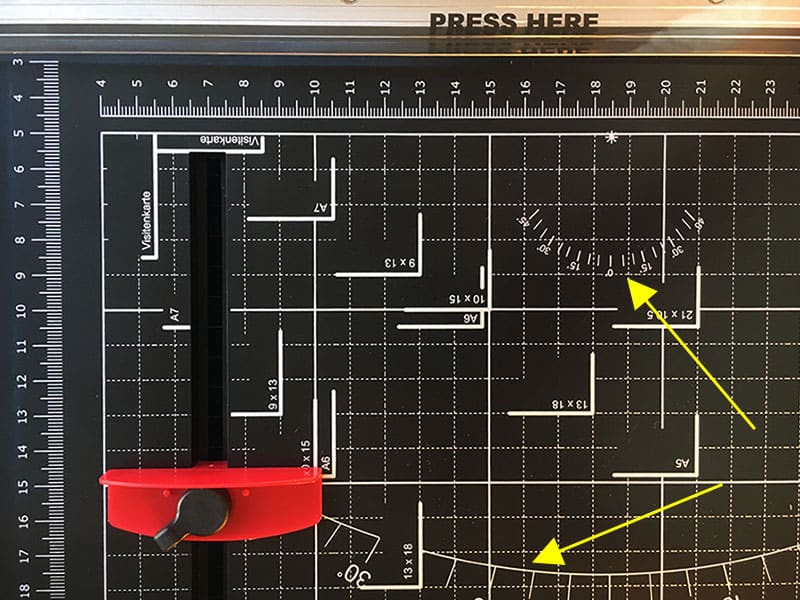

Winkelangaben / Winkelraster

Neben Längen- und Formatangaben sind aufgedruckte Winkel sehr hilfreich, wenn Sie verschiedenen Winkel zuschneiden möchten.

Mithilfe dieser Winkelraster lässt sich das Papier im gewünschten Winkel sauber und präzise zuschneiden. Deswegen sollte jeder, der regelmäßig verschiedene Winkel zuschneiden möchte, darauf achten, dass die Papierschneidemaschine solche Winkelangaben besitzt.

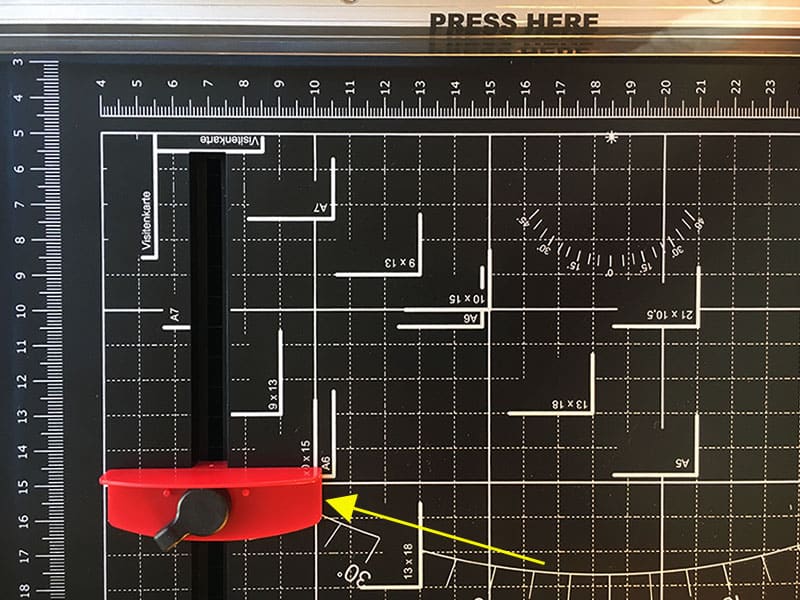

Der verstellbare Rückanschlag

Der Rückanschlag einer Papierschneidemaschine kann entlang der Winkelanlage verschoben werden. Ist er an der gewünschten Stelle positioniert, dann kann das Papier schnell und einfach eingelegt werden.

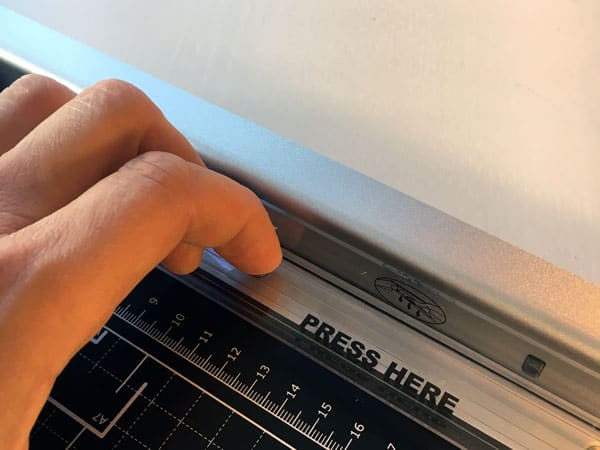

Die Pressung

Damit das Papier beim Schnittvorgang nicht verrutscht, muss es ausreichend fixiert werden. Entweder muss das Papier manuell angepresst werden oder der Papierschneider besitzt eine automatische Pressung. Mit einer solchen Anpressschiene wird das Papier durch einen entsprechenden Mechanismus ausreichend festgehalten.

Das Gewicht und Material einer Papierschneidemaschine

Das Gewicht einer Papierschneidemaschine sollte nicht vernachlässigt werden. Auch bei einem einfachen Gerät sollte auf das ideale Gewicht und auch auf das passende Material geachtet werden. Je stabiler die Schneidemaschine ist und, umso stabiler sie steht, desto einfacher ist es präzise und sauber zu arbeiten. Andererseits sind schwerere Geräte nicht so handlich wie leichte und kompakte Schneidemaschinen. Vor dem Kauf sollten Sie sich überlegen, ob die Maschine einen festen Arbeitsplatz bekommt oder nach dem Zuschnitt jedes Mal wieder verstaut werden muss.

Zusammenfassung der Eigenschaften von Papierschneidern

Die unterschiedlichen Modelle lassen sich bezüglich folgender Eigenschaften bewerten und vergleichen:

- Qualität der Klinge

- Schnittlänge, welche unter anderem das maximale Format bestimmt

- Sauberer und präziser Schnitt

- Unterschiedlichen Formatangaben und -größen

- Maximale Schnitthöhe und die maximal mögliche Stärke des Papiers

- Maximale Anzahl der Papierblätter, die in einem Arbeitsgang bearbeitet werden können

- Messskalen (Hilfsraster, Lineale, Winkelraster und DIN A Formate)

- Winkelanlagen und ein (verstellbarer) Rückanschlag für ein komfortables Arbeiten

- Ein stabiler und sicherer Stand

- Eine automatische Pressung, damit das Material nicht verrutscht

In unserem Vergleich von Papierschneidemaschinen haben wir viele unterschiedliche Modelle bezüglich dieser Eigenschaften bewertet und verglichen.

Welche Papierschneidemaschine passt zu mir?

Das kommt ganz auf den Anwendungsfall an. Wer bastelt, sollte eher zu einer Rollenschneidemaschine greifen. Diese sind eher für das Zuschießen einzelner oder weniger Blätter oder Fotos ausgelegt. Außerdem lassen sich mit einigen Modellen auch verschiedenen Muster (z. B. Zickzack) zuschneiden.

Hebelschneidemaschinen sind für all die, die lange gerade Schnitte benötigen oder dickere Stapel an Papier auf einmal bearbeiten machten.

Schneideplotter sind für all die, die Papier oder andere Materialien (z. B. Stoff, Leder oder Vinyl) in beliebige schneiden möchten, um daraus.

Wo kann ich eine Papierschneidemaschine kaufen?

Heutzutage gibt es zwei Möglichkeiten, eine Schneidemaschine zu kaufen. Entweder im Fachhandel oder Online.

Große Haushalts- oder Elektronikhändler und Fachgeschäfte für Fotografie und Bastelbedarf verkaufen Papierschneidemaschinen. Die Auswahl der Papierschneidemaschinen orientiert sich bei diesen an der Ausrichtung des Fachgeschäfts. Geschäfte für Bastelbedarf bieten Geräte zum Basteln an. Fotofachgeschäfte speziell für den Zuschnitt von Fotos geeignete Papierschneidegeräte. Große Händler besitzen meist eine breitere Auswahl.

Online-Händler bieten eine ähnliche Auswahl an Papierschneidemaschinen an. Tendenziell ist das Sortiment eines Online-Händlers größer als das eines normalen Händlers. Dafür muss länger auf die Lieferung gewartet werden.

Weitere Informationen zum Kauf im Fachhandel oder Online.

Was kosten Papierschneidemaschinen?

Der Preis einer Schneidemaschine hängt von verschiedenen Faktoren ab. Neben der Qualität spielen die Schnittlänge und -höhe neben der Ausstattung eine entscheidende Rolle. Einfach Papierschneidemaschinen gibt es schon für um die zehn Euro. Profigeräte können sogar 1000 € kosten. Wer zu Hause basteln möchte, der wird nicht mehr als 50 € ausgeben müssen. Ein vernünftiges Gerät für das Büro kann bis zu 150 € kosten.

Papierschneidemaschinen und ihre Schnitthöhe – ein Vergleich

Wie bereits erwähnt ist die Schnitthöhe ein wichtiges Kriterium für die Wahl der passenden Papierschneidemaschine ist die Schnitthöhe. Diese entscheidet, neben anderen Faktoren, wie viele Blätter in einem Arbeitsgang geschnitten werden können. Hebel- und Rollenschneider unterscheiden sich hier oft beträchtlich.

Die von uns ausgesuchten Rollenschneidemaschinen besitzen Schnitthöhen zwischen 0,2 und 2 Millimetern (Dahle 552). Im Gegensatz dazu bewegen sich die Schnitthöhen der Hebelschneider zwischen 0,5 und 4 Millimeter. Wenn Sie beabsichtigen nur sehr wenige Blätter auf einmal zu schneiden, dann lohnt es sich beide Typen von Papierschneidemaschinen näher zu betrachten. Wenn es jedoch Schnitthöhen über zwei Millimeter sein sollen, dann sind Hebelschneider klar im Vorteil.

Preis pro Schnitthöhe und Blattanzahl

Uns hat es interessiert, wie sich eine größere Schnitthöhe auf den Preis der Schneidemaschine auswirkt. In unserem beispielhaften Vergleich liegt der Preis* für Rollenschneidegeräte mit einer Schnitthöhe von 1 mm im Bereich von 15 und 25 €. Hebelschneider mit dieser Schnitthöhe sind zwischen 20 und 30 €* zu haben.

Da die verschiedenen Hersteller bei den Angaben nicht immer die gleichen Einheiten verwenden, haben wir für unsere Recherche folgende Regel angewendet:

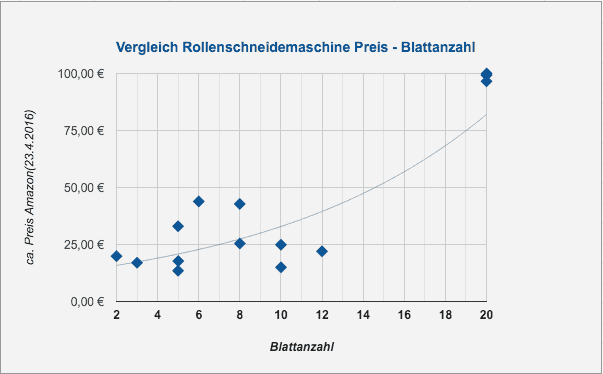

Das Verhältnis zwischen maximaler Blattanzahl und dem jeweiligen Preis* haben wir in der folgenden Abbildung dargestellt.

Bis zu einer Anzahl von zwölf Blättern sind Rollenschneidemaschinen verhältnismäßig günstig. Für 20 Blatt muss schon tiefer in den Geldbeutel gegriffen werden. Der Preis liegt im Mittel bei etwa 25 €. Für eine Schnitthöhe von zwei Millimetern (20 Blatt) liegt der Preis hingegen bei etwa 100 €.

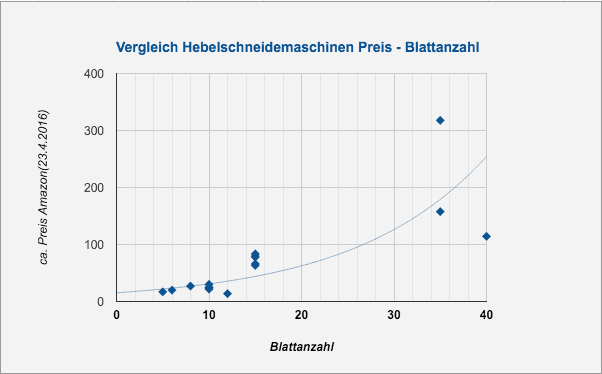

Die Preisspanne* für Hebelschneider sieht wie folgt aus:

Die beispielhaft ausgesuchten Hebelschneidegeräte sind bis etwa zwölf Blätter tendenziell etwas günstiger.

Hersteller von Papierschneidemaschinen

Novus Dahle GmbH & Co. KG (Dahle)

Die Novus Dahle GmbH & Co.KG gehört zur deutschen emco Group, welche in verschiedenen Bereichen tätig ist. Die Novus Dahle GmbH & Co. KG stellt Papierschneidemaschinen, Aktenvernichter und Flipcharts her und bietet ebenfalls Befestigungstechnik an. Bekannt sind die Papierschneider unter dem Markennamen Dahle. Zum Sortiment gehören Roll-, Schnitt-, Hebel- und Stapelschneidemaschinen. Diese werden in verschiedenen Preisklassen für unterschiedlichste Einsatzzwecke angeboten. Sehr beliebt ist die Dahle 507 Roll- und Schnittschneidemaschine und die Dahle 561 Hebelschneidemaschine.

Fiskars

Fiskars ist ein finnischer Hersteller, welcher unterschiedlichste Produkte anbietet. Besonders bekannt ist Fiskars für Gartenwerkzeuge. Außerdem gehören Papierschneidemaschinen und Papierschneider zum Sortiment.

Fellowes, Inc.

Fellowes ist ein amerikanisches familiengeführtes Unternehmen, das bereits seit 1917 besteht. Zum Produktportfolio gehören Büromaschinen, wie Papierschneidemaschinen, Laminiergeräte oder Aktenvernichter. Fellowes ist weltweit tätig und besitzt ebenfalls eine Niederlassung in Deutschland.

Ideal

Ideal ist ein deutscher Hersteller von Papierschneidegeräten aus Balingen. Neben Rollenschneidemaschinen werden auch Hebel- und Stapelschneider produziert und angeboten. Neben Schneidemaschinen gehören automatische Hefter, Aktenvernichter und Luftreiniger zu den Produkten von Ideal.

Preise inkl. MwSt., zzgl. Versandkosten / Letzte Aktualisierung am 25.04.2024 um 08:35 Uhr / Affiliate Links / Bilder von der Amazon Product Advertising API